WEARABLES

Printed electronics sensor solutions for smart health monitoring and elderly care wearables

Steve Paschky, Managing Director-Sales and Marketing at Saralon in Chemnitz, Germany, looks at the transformative impact of printed electronics in advancing wearable technologies for medical and elderly care. He explores the two approaches to integrating sensors into smart healthcare wearables and highlights the solutions Saralon offers for each.

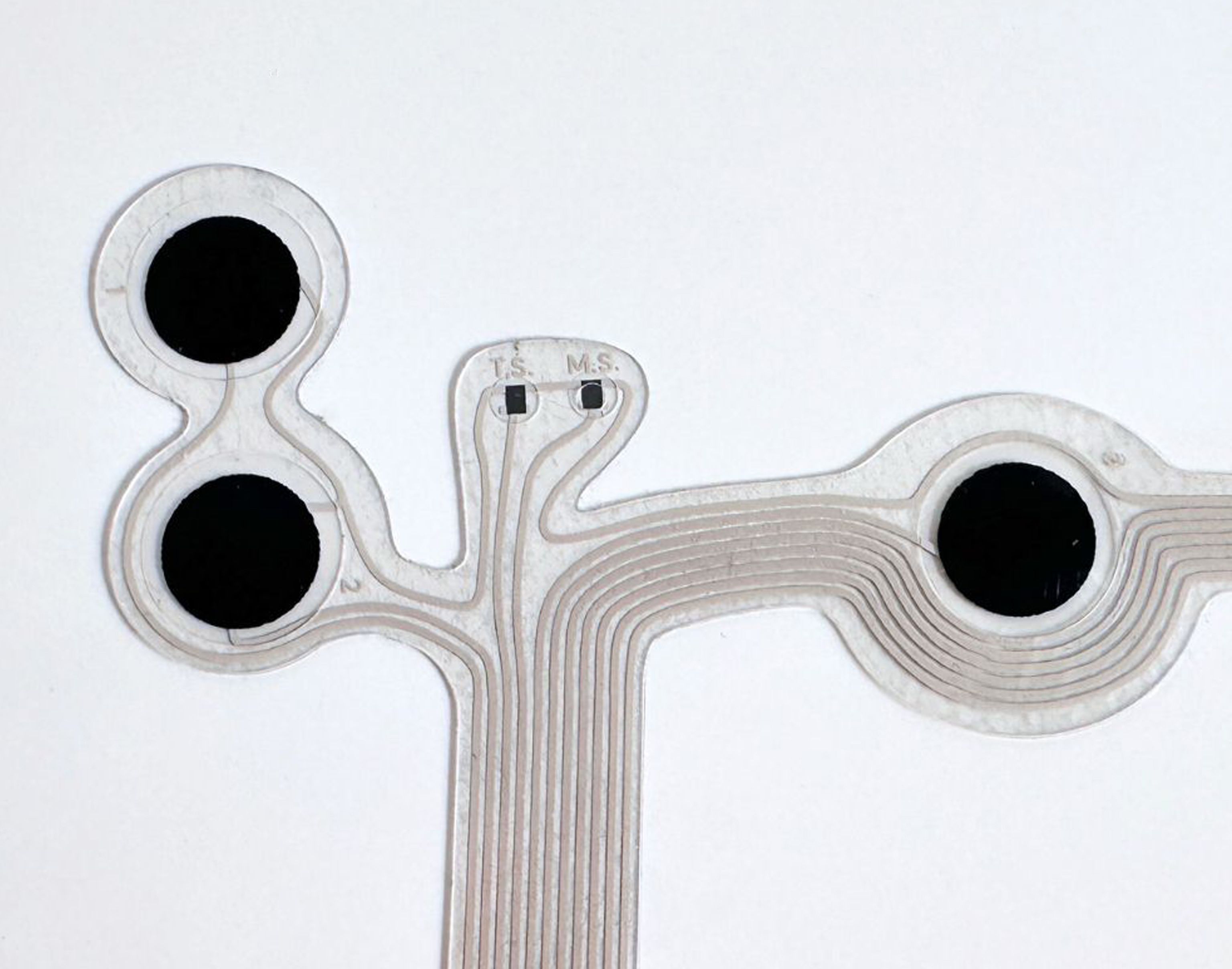

Integrated printing of pressure, humidity and temperature sensors using Saral Inks on PET. Image source: Saralon

Wearable sensor technologies hold great promise for addressing healthcare needs, particularly in remote patient monitoring (RPM) and elderly care systems, including ambient assisted living (AAL). These solutions are by definition preventative, using advanced sensing and monitoring systems to collect real-time data, anticipate problems, predict and prevent emergencies.

In elderly care, wearables must ensure safety and comfort without disrupting the daily lives of older adults. In short, they need to be comfortable, simple, effective and aesthetically pleasing. In the context of remote patient monitoring (RPM), the idea is to replace episodic doctor visits and occasional data collection with continuous data streams. This introduces a new paradigm where RPM is a means to gain predictive insights into health status by inferring trends from a large set of basic sensor data. The question then arises: Do we have the sensors we need to collect biometric and daily routine data?

In addition to the obvious criteria of accuracy and proven quality of such technologies, these sensors must overcome the human factor of resistance from consumers, physicians and healthcare

Stretchable hybrid electronics on TPU using screen-printable Saral SilverGlue Alpha 600 and Saral StretchSilver 800. Image source: Saralon

Two approaches to embedding sensors Printed electronics (PE) offers significant advantages in this context, enabling smart solutions to be integrated into flexible, bendable and stretchable surfaces that easily conform to the human body. PE enables the creation of invisible electronics and non-bulky, comfortable smart devices that are essential for wearables. There are two main strategies for embedding sensors in PE wearable devices:

- Using sensor inks to print on the chosen substrate.

- Mounting miniaturised sensors as SMDs on flexible and stretchable substrates using conductive adhesive inks.

Regardless of the approach, Saralon offers ink solutions to optimise the development process for PE wearable projects, ensuring that sensors can be effectively and efficiently integrated into healthcare wearables.

Inks for printing flexible sensors Printed flexible lightweight sensors easily adopt skin curvature. The development method is either direct printing of functional inks onto the chosen substrate such as plastic, paper or textiles or using transfer technology in the case of e-textile applications. Saral Sensor inks simplify the development of a variety of shapes and provide real-time data for wearable technology in the medical and elderly care sectors.

Saral TemperatureSensor 100 Temperature sensors with flexible form factors that conform to the curvature of the skin are essential in healthcare applications. Saral TemperatureSensor 100 is the temperature sensitive ink for easy integration into an additive printing process:

- Screen printable on textile, plastic or paper.

- Cost-effective production of a wide range of shapes and sizes.

- Ultra thin, flexible sensor format.

- Fast drying.

Creating a temperature sensor is simple. First a layer of SaralSilver ink is printed as an electrode. Then the Saral TemperatureSensor 100 is placed on top. These printed sensors are ideal for accurate and reliable measurement of temperatures between 20 and 60°C.

Saral PressureSensor 300 This is a carbon based piezoresistive pressure sensor ink for direct integration of pressure sensors during the printing process. Using Saral PressureSensor 300, a low cost, multi-cycle pressure sensor can be printed relatively quickly and easily. These are folded foils with fine printed Saral Silver 700 lines as electrodes and Saral PressureSensor 300 on top. Encapsulation is a simple screen printing process using Saral HotMeltGlue 800.

- Screen printable on textile, plastic or paper.

- Solvent based.

- Thermally dried.

ABOUT SARALON Saralon, based in Chemnitz, Germany, positions itself as industry leader in the development of functional and conductive inks and ready-to-use printed electronic boards for specific applications. Its products and services are divided into four groups: Saral Inks: A comprehensive range of individual conductive and functional inks that give printed electronics designers the freedom to choose based on the desired functionality (conductive, stretchable, sensing, thermoformable, heating, etc.). Saral Inks Sets: Specifically designed and developed sets of compatible inks for effortless integrated printing of high-value, highdemand electronic applications (printed battery, printed EC display, printed EL display, etc.). In this way, Saralon eliminates the need to invest extra time and money finding compatible inks for different circuit parts. InkTech: Know-how transfer including design files, printing guide and continuous professional support. Saral Electronics: Pre-printed functional boards (SaralLight, Saral- NfC, SaralSecurity) produced by Saralon using Saral Inks. With this portfolio of products and services, Saralon aims to simplify printed electronics, foster innovation and pave the way for a sustainable future in the electronics industry.

www.saralon.com

Saral HumiditySensor 400 Humidity monitoring is widely required in various elderly care and remote patient monitoring applications. Saral HumiditySensor 400 is a fast drying, humidity sensitive ink specifically designed for screen printing low cost sensors ideal for accurate and reliable measurement of relative humidity between 30 and 90%.

- Screen printable on textile, plastic or paper.

- Solvent based.

- Dries thermally

Screen printable conductive adhesive ink The hybrid approach of integrating conventional sensors with printed electronics to create flexible, durable and high performance devices is being widely adopted by wearable technology developers. To combine the best of form and function, Saralon offers screen printable SilverGlue Alpha 600, a heat activated adhesive for SMD mounting on flexible substrates.

Saral SilverGlue Alpha 600 This ink is a silver based adhesive designed to thermally bond SMD electronics to flexible printed electronics with several key benefits:

- Screen printable, eliminating the need for soldering or special dispensing equipment.

- Low curing temperatures of 100 to 120°C, ideal for use on plastics, textiles and paper.

- Enables high-speed production of hybrid electronics.

Printed electronics offers unique opportunities for the advancement of emerging smart technologies. By enabling invisible electronics and removing the complexity associated with bulky electronics integration, it is driving the current trend in wearable technologies, which are investing heavily in printed electronics.